After the production of the plate blanket, the structure is stiffened with the application of profiles (stiffeners) and a panel is created. The stiffeners are joined in the fillet welding process. In the following figures, a fillet welding gantry with 4 welding modules and hydraulic clamping device can be seen. With this technology, stiffeners can be welded with a web of up to 25 mm thickness.

Laser hybrid fillet welding gantry with hydraulic clamping

Laser hybrid fillet welding process simultaneously from both sides

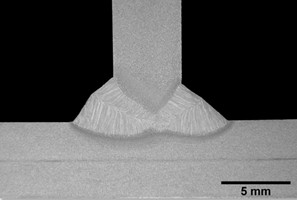

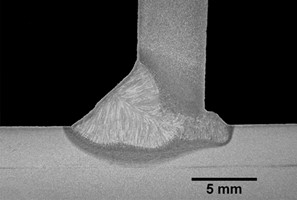

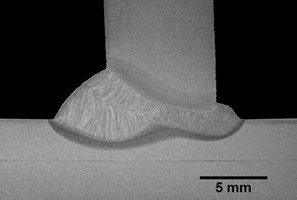

Full penetration laser hybrid welding, double-sided: stiffener t = 5 mm

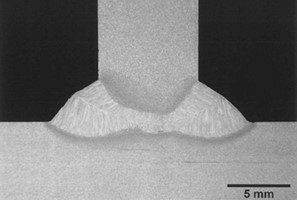

Full penetration laser hybrid welding, double-sided: stiffener t = 8 mm

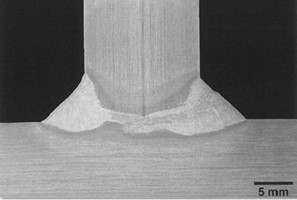

Full penetration laser hybrid welding, double-sided: stiffener t = 15 mm

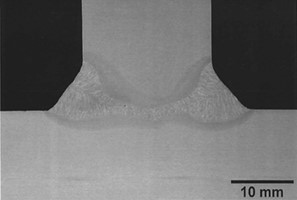

Full penetration laser hybrid welding, double-sided: stiffener t = 20 mm

Full penetration laser hybrid welding, one-sided: stiffener t = 5 mm

Full penetration laser hybrid welding, one-sided: stiffener t = 8 mm