First, prepared steel plates are welded by means of butt welding to large-area structures – so-called plate blankets. According to today's state of the art, plate thicknesses of up to 25mm can be processed. The following figures show a butt-welding gantry as well as the results of the butt seam welding process in the form of a plate blanket.

One side laser hybrid welding gantry with hydraulic clamping and edge preparation by milling

Plate blanket with 16m width after butt welding and after blasting if the contact lines for profiles.

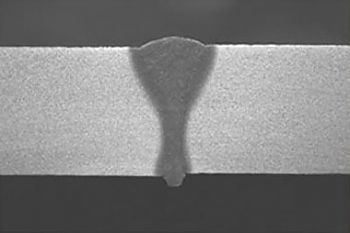

Laser hybrid welding seam: 10 mm

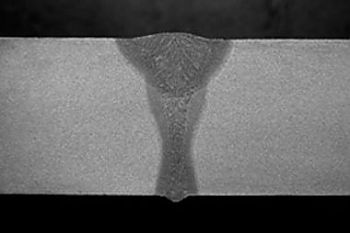

Laser hybrid + MAG tandem welding seam: 20 mm