As a specialist for innovative welding technologies and complex plant solutions, IMG began developing and integrating the laser hybrid welding process for industrial applications more than 17 years ago. This process combines the advantages of laser welding with those of arc welding: high welding speed, low heat input and good gap bridging.

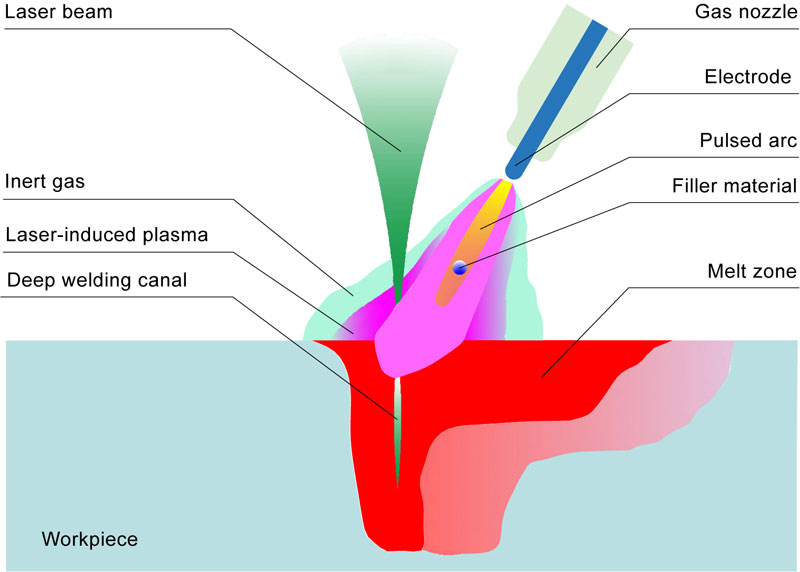

A focused beam of light with high energy density hits the welding seam in a focused manner. The energy penetrates deep into the material, evaporates it, and forms a vapor cavity. This is called a "keyhole". The arc following the laser fills the crater with additional material and forms an optimal flank connection.

The interplay of the two processes stabilizes the welding process enormously and reduces the formation of welding spatters. Due to the low linear welding energy, the component distortion is significantly reduced. This reduces straightening work to a considerable extent and significantly shortens the manufacturing process. In addition, a welding speed is achieved up to three times higher than submerged-arc welding, thus saving further process time.

Laser hybrid welding technology is used, for example, in panel production in shipbuilding. Structures with a width of over 24m (and corresponding welding seam length) can be produced. The production of panels takes place in the form of a flow-line production, see figure.

This picture shows laser-hybrid welding technology in a flat panel line for shipbuilding industry.