EXACT MEASURING.

The cutting and mounting gantry is equipped with a laser measuring system. It moves across the entire work area and identifies all workpieces and their positions. The necessary information about the workpieces are recorded in the course of the measurement. Following this, the data are processed with our developed software. All deviations between required data and actual data are determined automatically.

EXACT CUTTING.

Length cutting and contour cutting including weld seam preparation are carried out quickly and reliably. It comes with oxy fuel (largest bevel: 70°) or plasma (largest bevel: 45°). There is also the possibility to cut the workpiece in horizontal or vertical position. The consideration of the measured workpiece data enables perfect cutting shapes and an exact fitting accuracy.

EXACT MOUNTING.

After pipe cutting the workpiece remains clamped in the system. It can be moved in the X, Y and Z directions. The clamping device can be controlled separately. The workpiece is positioned precisely in height and to the necessary angle. It is not a problem to handle large pipe diameters and heavy weights. Complex assemblies can be installed quickly, accurately and without a crane.

VERY VALUABLE:

Our innovative cutting and mounting system offers great saving potentials. The effort in cutting, handling, assembling and reworking will be reduced to a minimum. Take advantage of our unique plant concept. Reduce your dependencies and increase the value of your production.

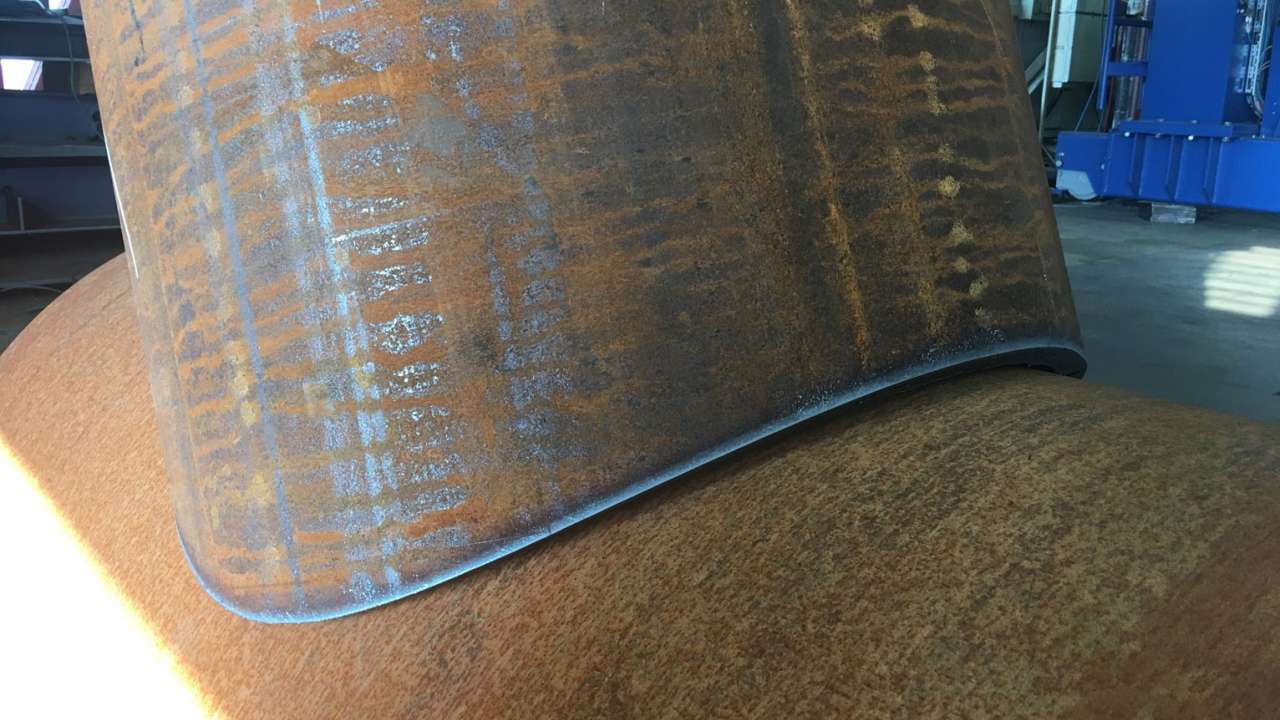

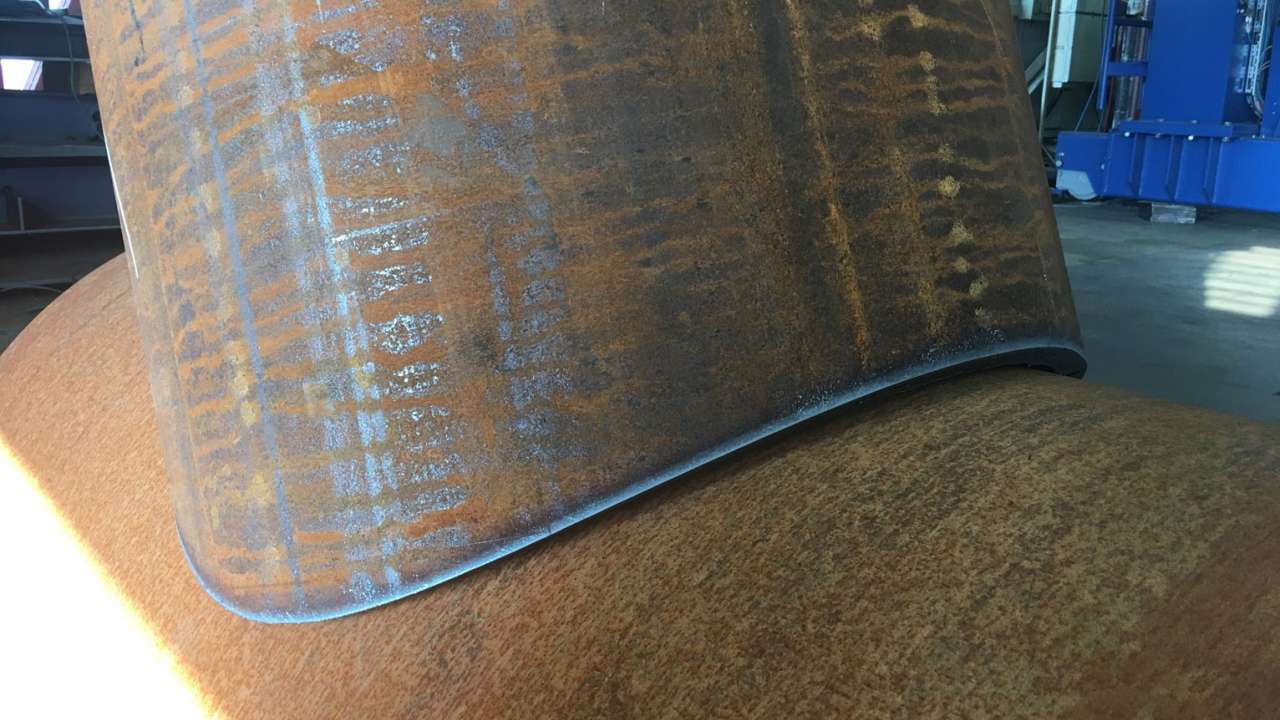

REAL CONTOUR DATA

Often starting material will have deviations in the dimensions, the roundness and the material thickness. Deviations from the target state may cause many preparations and much rework. The saving potentials in cutting and pre-assembling are large. The starting materials are analyzed with a laser measuring system before machining. The mounting area can be precisely identified. All data are documented by a special developed software system. Workpiece tolerances are considered during the programming of the cutting contours.

THE SHAPE YOU NEED

Complex contour cuttings are produced with real contour data. You get a high precision fit for pipe to pipe connections. Rework is mostly not required. The cutting robot can cut any shape you need. Choose between oxy fuel pipe cutting for thick material and steeper angles or plasma pipe cutting for fast processes and a wide range of materials. There is also the possibility to cut the workpiece in horizontal or vertical position. Large pipes and occurring moments do not cause problems.

SAFE TACK WELDING

No cranes and individual devices are required for handling and positioning of large pipe-to-pipe connections. Our cutting and mounting system equipped with the clamping device will secure the positioning of the connection pipe to the main pipe. The accessibility to the joining area is simple. The worker gets a user-friendly working area for safe tack welding.

WITHOUT CRANE SUPPORT

No retooling, repositioning or reclamping during process changeover between cutting and mounting operations. After pipe cutting the workpiece remains clamped in the system. It can be moved in the X, Y and Z directions. The clamping device can be controlled separately. The workpiece is positioned precisely in height and to the necessary angle. You’ll never need crane support or other technical devices. Reduce your effort for handling and mounting over 50%.